Realization of both decoration and electromagnetic wave shielding function

Electromagnetic wave shielding ink

Good news for those who are considering about process reduction and functionality improvement by realizing both decoration and electromagnetic wave shielding function!

It is possible to add an electromagnetic wave shielding function during the decoration process. It contributes to strengthening

EMC measures (against noise emission and intrusion) and cost reduction of electronic devices.

1. How Electromagnetic Wave Countermeasures work

1.1 Principle of blocking incident electromagnetic waves

There are two main principles used to prevent incident electromagnetic waves. One is to reflect incident electromagnetic waves at the surface.

The other is to attenuate the incident electromagnetic waves inside the absorber. The loss due to this absorption is consumed as electromagnetic waves are converted to heat inside the absorber.

To be precise, multiple reflections of electromagnetic waves are generated inside the shielding material, but the value is usually small and negligible.

| Principle | Details of Principle | Related variables |

|---|---|---|

| Reflection | Electromagnetic waves are reflected on the surface of shielding material. | Conductivity of the shield material regardless of the thickness of the shield material. |

| Absorption | Electromagnetic waves are converted to heat and consumed inside the absorber. | Frequency of electromagnetic waves, thickness, magnetic permeability and conductivity of the absorber. |

| Multiple reflection | A phenomenon where electromagnetic waves are reflected multiple times inside the shield material. Some waves pass through the shield material and reduce the loss effect. | Normally, the value is small enough to ignore. |

2. Electromagnetic wave shielding ink (Conductive ink)

2.1 Mechanism of ink for electromagnetic wave shield

Electromagnetic wave shielding ink can realize electromagnetic wave shielding function mentioned above by having a conductive function.

This ink enables to reduce the leakage of electromagnetic waves which is generated inside electronic devices and the intrusion of external electromagnetic waves.

Shielding inks for electromagnetic waves can provide shielding functions through printing, allowing for a high degree of freedom and compatibility with decorations, and are easy to introduce.

Moreover, it contributes to process reduction, lightweight and thinner, etc., by substituting with other methods (details will be described later).

2.2 Excellent features of electromagnetic wave shielding ink

| Excellent functionality | Details |

|---|---|

| Inexpensive and simple process |

|

| Achieve both shield function and decoration |

|

| Free adjustment of print pattern and ink layer thickness |

|

| Also applicable to antistatic |

|

2.3 Fields of application of electromagnetic wave shielding ink

Two measures: today’s electronics strictly require prevention of malfunction by noise emission (EMI or emission) and noise intrusion (EMS or immunity), that is, EMC measures (EMI measures + EMS measures).

However, due to increase use scene of electronic devices owing to the miniaturization and higher performance of them, the noise issues are not solved by only one absolute measure, but being solved by integrating multiple measures.

Under such circumstances, this electromagnetic wave shielding ink has become an excellent technology to realize relatively easily reinforcing EMC countermeasures.

| Fields of application | Obtainable effect |

|---|---|

| Touch panel |

|

| Electronic device housing |

|

| Antistatic measures for electronic devices |

|

3. Basic performance value of electromagnetic wave shielding ink

3.1 Conductive performance of electromagnetic wave shielding ink

The following is the reference values of the ink layer thickness value and surface resistance value when printing the electromagnetic wave shielding ink under the recommended conditions.

| Ink name | Surface resistance value | Ink layer thickness | Compatible base material |

|---|---|---|---|

| MRX-HF 00127 TAU DS Brown | ≤ 1Ω | 14µm | PET、PC etc |

| MRX-HF 00127 TD DS Gray | ≤ 200Ω | 14µm | Same as above |

| MRX-HF 00127 TAU DS Black | ≤ 10,000Ω | 10µm | Same as above |

| GLS-HF 00127 TAU DS Black | ≤ 2,000Ω | 8µm | Glass, Polyamide |

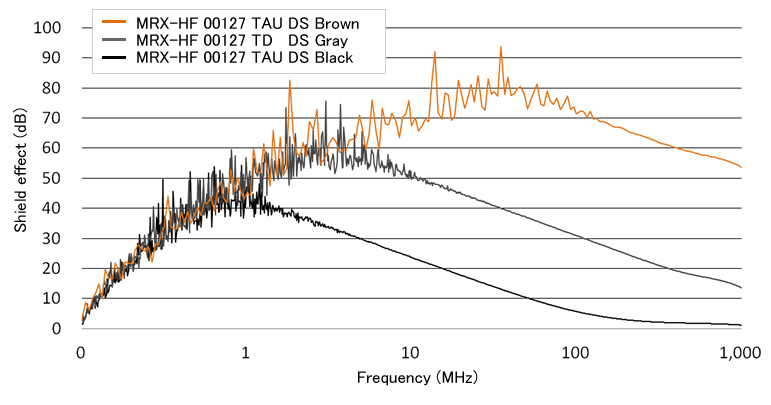

3.2 Shielding effect of electromagnetic wave shielding ink against electric field

The shielding effect of MRX-HF 00127 against the electric field is as follows. (Substrate: PC, ink layer thickness of solid printing: brown and gray 14µm, black 10µm) In addition, more complicated shield effect adjustment is possible, as adjustment of ink layer thickness and partial printing by multi-layer printing are also possible.

4. Example of using ink for electromagnetic wave shielding

4.1 Example of solid printing of electromagnetic wave shielding ink

This is printing example of GLS-HF 00127 TAU DS Black and Gray (substrate: glass) Because these can realize beautiful black or gray only by itself, it is possible to add a shield function and anti-static function simply by switching the decorative ink of the same color.

This is a printing example of MRX-HF 00127 TAU DS Black, Brown and MRX-HF 00127 TD DS Gray (substrate: PC) Because these can be printed in multiple layers, it is also possible to pursue both shielding function and designability by using MRX-HF 00127 TAU DS Brown, which has a high shielding effect.

4.2 Example of compatibility between electromagnetic wave shield and other functions (application to display)

This is an application example for a display of MRX-HF 00127 TAU DS Black that has both the electromagnetic wave shielding function and transmission of light (substrate: PC). Owing to the high degree of freedom of printing, electromagnetic wave shielding inks are effective when applied to special parts that require fine adjustment.

- Related technology information

- Related event information

- Related inks