Coexistence of excellent scratch resistance and the design.

Introduction of UV TAF (A) Clear

A Special News to those who are in charge of developing automotive meters and home appliances!

In this technical report, we would like to introduce technology which supports the surface design of the polycarbonate material and polyester film and its protection at the same time.

1. Coexistence of excellent resistance to abrasion and scratch

and the design

1. Excellent resistance to abrasion and scratch

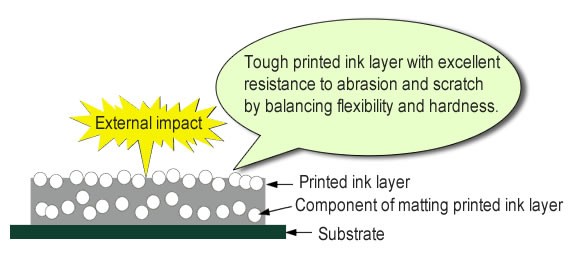

UV TAF (A) Clear can form tough printed ink layer with resistance to abrasion and scratch by balancing flexibility with hardness.

Providing unique texture and moist finished feel by hand, TAF (A) Clear is commonly used for designing name plates and protection of printed ink layer.

2. Realization of wide range of surface finish such as matte or

texture, etc.

UV TAF (A) Clear provides wide variety of surface finish such as matter or texture, etc.. These combinations realize surface finish with excellent design.

Its unique texture and finish make it possible to create printed substrates with more luxurious looking.

2. Characteristics and utilization of UV TAF (A) Clear

1. Excellent function of UV TAF (A) Clear

- Excellent resistance to abrasion and scratch

The balance of hardness and flexibility provides printed ink layer structure which is quite hard to be damaged. - High flexibility

Flexible printed ink layer with folding property and punching resistance is provided. - Excellent design characteristics

Combination of wide variety of surface finish such as matte or texture, etc. can realize surface finish to suit your taste.

2. Application of UV TAF (A) Clear

UV TAF Clear, making full use of its resistance to scratch and abrasion and the characteristics of luxurious-looking finish, provides the following applications for the purpose of design printing and protection of PC and PET material surface.

| Application | Contents |

|---|---|

|

Overcoat Clear for name plate

|

Protective laminate is not required because of resistance to abrasion and scratch Its flexibility prevents post-forming processes from defects. |

|

Overcoat Clear for panel switch

|

Flexible and excellent key stroke resistance. There is no crack in use.

|

3. Standard of UV TAF (A) Clear

UV TAF (A) Clear needs printing by designated mesh to demonstrate its performance.

The following table indicates optimum printing mesh and finish of each Standard Clear.

| Standard Clear | Print mesh | Surface finish |

|

UV TAF(A)100T Matt Clear

|

T-300 |

Full matt finish focusing on the sense of touch

|

|

UV TAF(A)100 Matt Clear

|

T-250

|

Full Matt finish

|

|

UV TAF(A)200 Matt Clear

|

T-200

|

Semi-matt (70 %) finish

|

|

UV TAF(A)300 Matt Clear

|

T-150

|

Quarter-matt (30 %) finish (Customized color)

|

- Related event information

- Related inks