Coexistence of IR transmission function and the design

Introduction of IRX-HF ink

Good News to those who are in charge of development and consider high functionality of smartphones.

In this technical report, we will introduce technology that allows IR transmission function and the design to coexist.

1.Coexistence of IR transmission function and the design

1. What is transmission function of IR (infrared light) and specific

visible light rays?

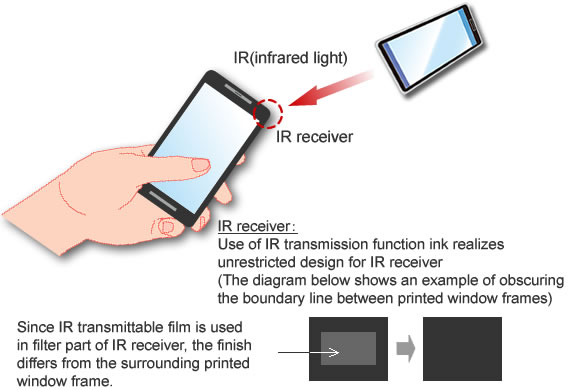

The current smartphone touch panels have IR receiver and visible light sensor built in to realize functions such as IR (infrared light) data communication or screen illuminance adjustment tailored to environment.

Conventionally, finish of the filter part where sensor was built in was different from the other exterior part depending on attachment of IR transmittable film (which transmits IR light only).

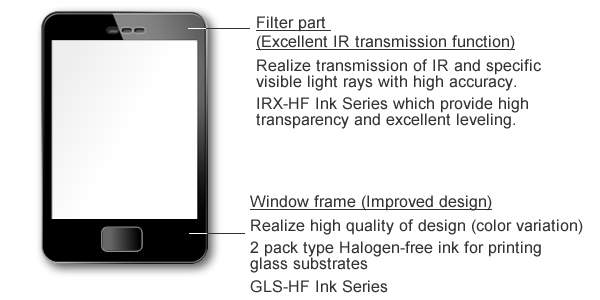

However, by using ink with function of selective transmission of IR and specific visible light rays for filter part, it is possible to maintain sensor function by obscuring boundary line of hue, for example, between filter part and surrounding printed window frame.

2. Coexistence of IR transmission function and the design

in touch panel of smartphone

Combination of GLS-HF ink series for glass substrates and IRX-HF ink series of IR transmittable ink (IR transmitting Ink) realizes both IR transmission function and unrestricted design on touch panels.

2. Characteristics of IRX-HF Ink Series

1. Excellent function of IRX-HF Ink Series

-

Selective control of transmitted wavelength

Selectively control transmission of IR (Infrared light) and specific invisible light rays by color matching. - High transparency

Selectively transmit IR and visible light rays with high transmittance rate. - Excellent leveling

Prevent diffused reflection of filter part and malfunction of sensor. - Excellent environmental response

There is no intentional use of Halogen compounds (Chlorine Cl, Bromine Br).

(Cl ≤ 900ppm, Br ≤ 900ppm, Cl+Br ≤ 1500ppm)

2. Resistance value of IRX-HF Ink Series

Resistance value of IRX-HF Ink Series is as follows.

(These test results are only for lab purposes. We do not guarantee the results.)

| Test item | Test conditions | Test result |

|---|---|---|

| Adhesion | JIS K 5600-5-6 (Cross-cut test): ISO 2409: 1mm interval 6X6 cuts, cellophane tape and peel | 0 (No peel-off) |

| Scratch hardness | JIS K 5600-5-4: ISO 15184 Scratch hardness (Pencil method), 750g weight, Pencil hardness not to make scar | 2H |

| Heat | JIS K5600-6-3, ISO 3248: 80°C, 1000H, check appearance and peeling off from substrate | No defect |

| Hot water | JIS K 5600-6-2:ISO 2812-2, Dip 72 hours in 60°C warm water, check appearance and peeling off from substrate | No defect |

| Humidity | JIS K 5600-7-2(continuous condensation):60°C, 95%RH, 1000 hrs. Check appearance and peeling off from substrate. | No defect |

| Boiling water | Dip 24hrs in boiling water, check appearance and peeling off from substrate. | No defect |

| Scrub | Gakushin scrub tester, with cotton, 500g weight, 1000 times back and forth, check color fade | No defect |

| Light fastness | ISO 2809:Fade meter with carbon arc, Black panel temp. 63+/-3°C, check color fade and peeling. (1000hrs) | No defect |

| Accelerated weather |

Weather meter with carbon arc, Black panel temp. 63+/-3°C, raining rate 18min/120min, check color face and peeling. (1000hrs) |

No defect |

* Drying conditions: 150°C, 30 minutes

* Substrate used: Glass plate

* Stencil used: T-350 Mesh

* Ink used: IRX-HF base ink,

Z-705 Solvent (5% thinning), GLS Glass Promoter (0.5%)

- Related technology information

- Related event information