Halogen free, environment-friendly 2 pack type ink and Binder

Introduction of Halogen Free, Environment-friendly Inks

As for Environmentally friendly Halogen Free Ink, we would like to introduce 2 pack type IMD/FIM Ink with no intentional use of Halogen compounds (Chlorine (Cl), Bromine (Br)) and non-inclusive of Benzene, Toluene, Xylene, Isophorone.

1.Background and Effort of Teikoku Inks for Halogen Free movement.

1-1. Background of Halogen Free movement

Some Electrical Devices and Mobile Phone related manufacturers are promoting non-inclusive of Halogen substances (Chlorine (Cl), Bromine (Br)) which could cause to release environmentally hazardous substances during the incineration.

Halogen substances are used mainly as compound of flame retardant, vinyl chloride, Chlorine Vinyl Acetate Copolymer Resin, pigment, etc.

Since this requirement of Halogen restriction has not yet been enforced by law, and it is voluntary control as of November 2009, Teikoku is corresponding to this matter by request of each customer. But we basically use following standard.

Standard condition of Halogen Free (as a final product)

- Content of Bromine (Br): below 900ppm (below 0.09%)

- Content of Chlorine (Cl): below 900ppm (below 0.09%)

- Content of Bromine and Chlorine: below 1500ppm (0.15%)

Other Halogen elements such as Fluorine (F), Iodine (I), and Astatine (At) are excluded from self voluntary control.

1-2. Effort of Teikoku for Halogen Free movement

Teikoku has been providing following Environmentally Friendly Halogen Free 2 pack type IMD/FIM Ink and Binder to reduce the amount of hazardous substances released in the environment.

2.Special Feature of Halogen Free Ink for forming

- Teikoku is not intentionally using Halogen compounds (Chlorine (Cl), Bromine (Br)) and non-inclusive of Benzene, Toluene, Xylene, Isophorone, Vinyl chloride resin. They are human and environment friendly inks.

- We have achieved the elimination of environmental hazardous substances and maintained high standard of requirements for flexibility and washout resistance (rigidity and resistance against high temperature) used for IMD/FIM Ink.

Special Feature of Each Ink

| Product | Special Feature of Ink | Substrate | Example of Application |

|---|---|---|---|

| IPX- HF | 2 pack type screen ink for IMD/FIM

Excellent resistance of ink layer ⇒ Applicable for surface printing High heat resistance and designed to have less incidence of washout problem around gates. Applicable for wide range of substrates and suitable for automobile, home appliances, mobile phone, and other usages. |

PC Treated PET PC/PBT PMMA |

Nameplate, interior Mobile phone Nameplate for Exterior of PC Display |

| INQ-HF | 2 pack type screen ink for IMD/FIM

Excellent flexibility and especially, suitable for TPU substrate material. Good for deep-draw forming |

TPU flexible material |

Mobile phone Membrane switch Nameplate for home |

| IMB-HF006 | 1 pack type Binder for IMD/FIM (Binding layer)

It is 1 pack type and possible to print same way as standard screen printing ink. It will be used as Binding Layer with forming resin when 2 pack type ink is used. |

Molding resin such as ABS, PMMA, AS, etc. | Used as Binding layer with molding resin when IMD/FIM is applied. |

| IMB-HF009 |

It will be printed as Binding layer for 1 pack or 2 pack ink for molding such as IPX Ink Series. For Mirror Ink |

PC resin, PMMA resin | Used as Binding layer with molding resin when IMD/FIM is applied for Mirror Ink. |

For Safety and Handling

- SDS (Material Safety Data Sheet) is available. If you need SDS for our products, please contact us for further inquiry.If you are using our products, please refer to SDS and take proper procedures and usage under your own risk.

- For the prevention of contamination of Halogen compounds, please do not use other than designated solvents and catalysts.

- Please check the Squeegee, Emulsion, Equipments, Substrate, etc. for possible contamination of Halogen compounds before usage.

3.Example of using 2 Pack Halogen Free Ink for Forming

Using this Ink, you will be able to achieve both reduction of Environmental Risk by Halogen Free Movement and differentiation of the product with superior design.

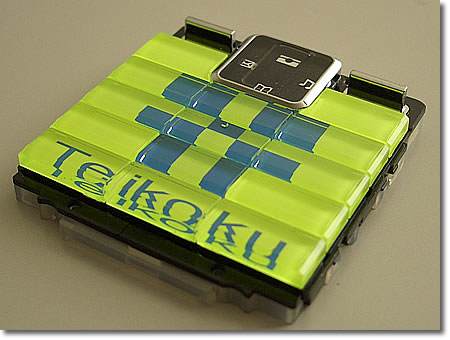

3-1. Mobile phone (Example of using IPX-HF Ink)

Halogen Free requirement has been started in some electrical parts, such as mobile phones.

Mobile phone (1)

Mobile phone (2)

Mobile phone (3)

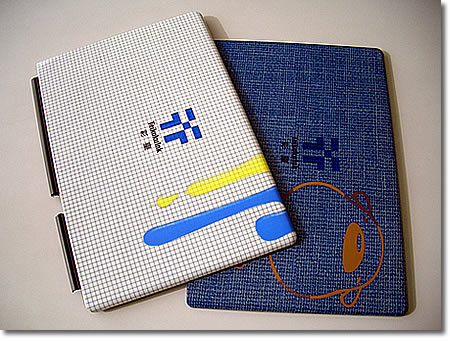

3-2. Personal Computer (Example of using IPX-HF Ink and IMB-HF 006)

Using Halogen Free Inks for top panel of PC, it will be able to achieve both differentiation of your design and Halogen Free requirements at the same time.

3-3. Other plastic Products ( Example of using INQ-HF Ink)

Halogen Free Ink can be used for Film Insert Molding. (The picture shows the lure for fishing as one of the examples.)

- Related technology information

-

- 150: Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- 151: Technology lecture for FIM/IMD 2nd session: Explanation of the screen printing process.

- 152: Technology lecture for FIM/IMD 3rd session: Explanation of the Forming Process.

- 153: Technology lecture for FIM/IMD Final session: Explanation of the Injection Process

- Related event information