Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

In this issue, we are showing the CONCEALED PRINTING as an example of utilization of IR Transmittable Ink (IR Transmitting Ink) and its special characteristics, which can provide wide variation of designs and functionalities for customers' products.

1.What is IR Transmittable Ink (IR Transmitting Ink)?

IR Transmittable Ink (IR Transmitting Ink) has the special characteristics which allow IR (Infrared ray) to penetrate through the ink, but it will block the visible light and ultra violet ray (Sun light and etc.)

As for the designated wavelength, transmittance rate can be adjusted by different formation of printed ink layer on the transparent sheet.

Since the ink layer will block light rays other than the Infrared radiation, this ink is commonly used for signal light receiving window of remote controller and infrared ray receiving part of the mobile phone.

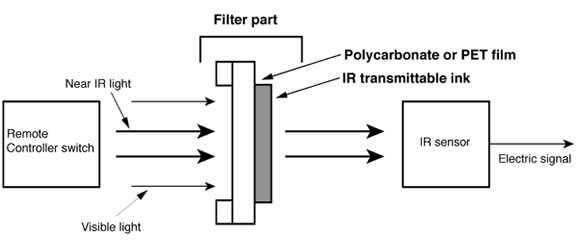

– Reaction Mechanism –

1) Outgoing near-infrared ray (900-1100nm) will penetrate through the filter (printed area by IR Transmittable Ink (IR Transmitting Ink)).

(It will prevent malfunction of device from fluorescent lamp and visible light by blocking the ultraviolet and visible light.)

2) Infrared ray, which has passed through the filter, will be received by the sensor.

3) Received infrared ray will be changed to electric signal, then amplified to activate the switch by phototube of sensor.

Figure1: Mechanism of remote controller, infrared ray sensor, and IR Transmittable Ink

(IR Transmitting Ink)

2.Special characteristic of Teikoku IR Transmittable Ink

(IR Transmitting Ink)

1. Pigment base ink

Generally, IR Transmittable Ink (IR Transmitting Ink) is known to use dye compound, but this type of ink does not have strong resistance in certain areas and it has a weak point of dyeing the squeegee and the stencil. Therefore we would like to recommend pigment base IR Transmittable Ink.

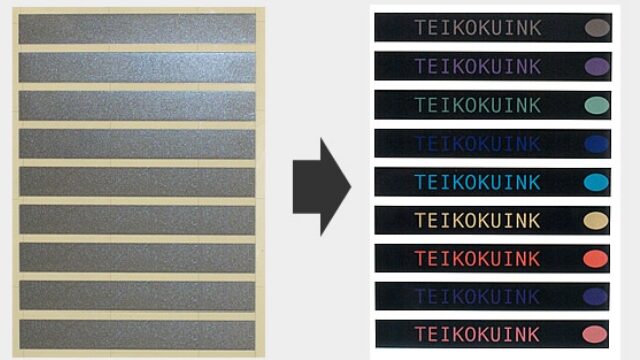

2. Hue

IR Transmittable Ink has a special characteristic of blocking Ultra violet and Visible light and it has a function of infrared ray to penetrate. Also in order to conceal the inner structure of filter from outside, the color of ink surface will be blackish color.

There is a limitation of hue adjustment due to functionality of the ink, however transmitting color can be controlled. (Transmittance rate varies by different colors) In addition, we have metallic inks for additional hue variation of the ink, but the transmittance rate of infrared ray will be 10 to 20% lower than standard IR transmittable inks.

Figure 2: Examples of color variation of IR Transmittable Ink

3. Halogen Free

We have been developing Halogen Free type of IR Transmittable Ink and does not intentionally use compounds of Chlorine (Cl) and Bromine (Br) in raw materials. Halogen free means Cl < 900 ppm, Br < 900 ppm, and Cl + Br < 1500 ppm. Currently, we have IPX-HF, MRX-HF, and GLS-HF Ink Series for Halogen Free.

4. Compatible with various types of substrate materials

We have various types of ink series. If you have any questions regarding substrate materials and inks, please feel free to contact us.

3.Example of concealed printing by using Light Transmittance function.

As already illustrated in the above, IR Transmittable Ink has various colors available and with multi-printing of metallic inks, you will have wider selection of hue variation.

Using concealed printing with light transmission, it enables to create various types of decoration.

Special note 1) Transmittance rate will slightly vary by transmitting color.

Special note 2) When metallic ink is multi-printed, infrared transmittance rate will decrease by 10 to 20%.

Examples of concealing prints which are multi-printed with metallic ink and IR transmittable Ink with different type of visual transmitting light.

The followings are the photos of sheets which are multi-printed with IR Transmittable Ink and Metallic Ink, and the photos with transmitting visible ray by backlighting.

You will notice that without the backlighting, you can not see the concealed printings.

Figure 3: Multi-printed on the sheet with IR Transmittable Ink and Metallic Ink. (Without backlighting and with backlighting)

The following is the enlarged photo of multi-printing on the sheet with IR Transmittable Ink and Metallic Ink.

Even enlarged photo, we can not distinguish the concealed printings.

Figure 4: Multi-printed sample of IR Transmittable Ink with Metallic Ink (Enlarged Photo)

The following is the enlarged photo of printing with backlighting.

It will be possible to create a new design with a combination of various types of Transmittable inks.

Figure 5: The above photo is the sample of sheet with backlighting. (Enlarged photo)

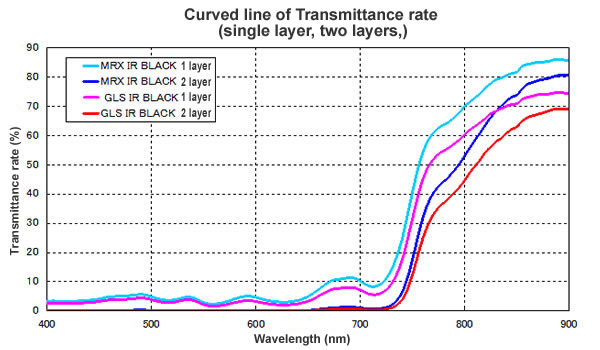

4.General Transmittance Rate (Graph)

The above graph is the example of Curved line of Transmittance rate. The chart shows single layer and 2 layers of MRX IR Transmittable Ink (Substrate: MR200) and GLS IR Transmittable Ink (Substrate: Glass).

– Detail of the Graph –

For the Graph of Transmittable Rate, horizontal line indicates the wavelength of light (nm (nanometer)) and vertical line indicates the transmittance rate (T%).

As the value of T% goes higher, the printed ink layer will allow such corresponding color of T% to be passed through. The visible ray ranges from 380 to 780 nm and if the wavelength is shorter, it is ultraviolet ray and if the wavelength is longer, it is infrared ray.

* In general, the transmittance rate is the average value of transmittance rate which passes through each point of 380 to 780nm.

- Related technology information

- Related event information

- Related inks