Product overview

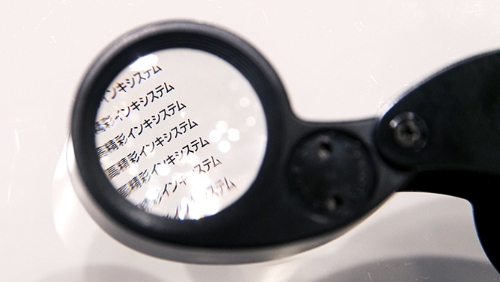

XGL-HF is the ink which reproduce solid printing and fine line pattern faithfully and enables stable printing of 100µm width fine line with quite high accuracy. XGL-HF ink is two pack type screen ink. It has excellent printing stability, adhesion, and resistance, which are essential for glass printing.

- High Definition Ink

Application

- Glass printing for smartphones, tablets, etc.

-

Automobile, Motorcycle

-

Home Appliance (IoT)

-

Smartphone, Tablet, Smart watch

-

Sensor

-

Game

-

Others

Features, Function

- Free of halogen (Chlorine Cl, Bromine Br) compounds and naphthalene.

- Excellent stencil stability, suitable for large format printing.

- A wide variety of colors are available for colorful printed materials.

- Excellent adhesion to glass and various types of resistance enable a wide range of applications.

- Electrical properties

- Multi color setting

- Halogen Free

- Fine printing

- Fast dry, slow dry

Substrate

- Glass plate

- Glass

Dilution

- Z-705 SOLVENT(slow)Dilution: 0 to 5%

- *Do not use other solvents as they may adversely affect curing, adhesion, stencil stability, or other properties.

Catalyst, Promoter mixing

- XGL-HF GLASS PROMOTER 0.5% (Be sure to add it, otherwise it will not adhere)

- Pot life: 6 hrs.

- *Pot life (usable time) is about 6 hrs. The ink does not turn to gel after 6 hours but adhesion and resistance become inferior. Please mix only enough to use.

Promoter

- XSM-40 DEFOAMER less than 1%(For anti-foam and improvement in leveling)

Recommended cleaner

- Screen Cleaner L2

Mesh

- L 355 Mesh (Coverage of 939 NC Black is about 80m2/kg at L-355 mesh)

- *Recommendation: L-screen 355 mesh made by NBC Meshtec

- *T 350 mesh can also be used for printing

Drying

- 160℃ 30 min

- Overprint

Each layer 160℃ 10 min(tack-free)

Final layer 160℃ 30 min

- *Ensure sufficient drying

Standard colors

-

HF001 VICTORIA

-

HF169 SCARLET

-

HF189 RED

-

HF239 LIGHT YELLOW

-

HF399 BLUE

-

HF529 ORANGE

-

HF589 MAGENTA

-

HF679 WHITE

-

HF829 VIOLET

-

HF939NC BLACK

Caution

- Due to the possibilities of contamination with halogen compounds, only designated solvents and catalysts can be used.

- Please check the squeegee rubber, emulsion, materials and substrates before use, as they may contain halogen compounds.

- Checking before production: Adhesion and resistance properties may change due to differences in substrates, processes, printing and drying conditions. Be sure to check the adhesiveness and resistance properties before mass production printing.

- Ink shelf life: 12 months from production date, unopened.

Safety

- UN No.: Not classified in the definition

- UN Classification: Not classified in the definition

Handling

- Use safety gloves and eyeglasses to protect skin and eyes. If the ink comes in contact with skin, wash with soap and plenty of water(or lukewarm water)and consult with a doctor.

- Containers should be closed tightly after use and stored in a cool and dark place.

- SDS is available upon request. Please request a copy and read it carefully before handling the products.

Resistance

| Test item | Test Conditions | Test results |

|---|---|---|

| Adhesion | JIS K 5600-5-6:ISO2409(cross-cut),1mm interval 6×6, cellophane tape and peel | 0(no peel) |

| Pencil Hardness | JIS K 5600-5-4:ISO 15184(pencil),750g weight, Hardness of the pencil which does not make scar | 2 hrs. |

| Heat | 80℃、168 hrs., check appearance and peel off from the substrate | No defect |

| Hot Water | Soak 72 hrs., in 60℃ hot water, check appearance and peel off from the substrate | No defect |

| Heat and humidity | 60℃,95%RH 1000 hrs., check appearance and peel off | No defect |

| Boiling | Soak 24 hrs. in 98℃ boiling water, check appearance and peel off | No defect |

| Scrub | Gakushin scrub tester, cotton, weight 500g, 1000 back and forth, check color fade | No defect |

| Accelerated Weathering | (Xenon Lamp) Weather meter, 1000 hrs, BP Temp. 63+/-3℃ Raining rate 18 min/120min,check color fade and pee off | No defect |

| Accelerated Light fastness | (Carbo arc)Fade meter 1000 hrs., BP Temp.63+/-3℃, check color fade and peel off | No defect |

Test Condition

- Test conditions 【XGL-HF 939NC Black】【XGL-HF Glass Promoter 0.5%】 【160℃ 30 min】【L 355】【Substrate: Glass plate】

- Above resistance test results are measured results in our laboratory and they are not guaranteed values.

- Information contained in this catalog may change without prior notice.

FAQ

-

What are screen inks for glass substrate printing? And what are their characteristics?

-

For printing on glass substrate, GLS-HF ink series , a two component type Halogen Free ink for printing on glass substrates is recommended.

The GLS-HF ink series is characterized by the fact that it is an organic ink, unlike the inorganic inks conventionally used for glass substrate printing.

Therefore, GLS-HF ink has excellent functions to solve the problems of inorganic inks (burning type ink) such as “lack of color variation” and “environmentally hazardous substances”, etc.

Related link

Introduction of GLS-HF ink (1) -

Is there any information related to the high value-added flat panel and touch panel?

-

We would like to introduce the high value-added glass substrates for flat panels, touch panels, etc. using the technologies we offer.

From a design stand point: *Realize various color variations on glass substrates. *High opacity Black and high opacity White that can be applied to window flame of touch panels.

From a function stand point: *Providing IR transmittance functions, *Malfunction prevention by non-conductive black, *Reduction of environmentally hazardous substances, etc.

Related links

Introduction of IRX-HF

Introduction of GLS-HF (4)

Introduction of GLS-HF (3)

Introduction of GLS-HF (2)

Introduction of Functional Black ink -

What is high opacity black and white?

-

This function provides a beautiful black or white color with high opacity even in environments where backlights are used, such as outer frames of flat panels and touch panels.

Related link

Introduction of GLS-HF (3)

- Related technical information

- Related event information