Past events

Exhibition Report of TECHNO-FRONTIER 2023

Event outline

TECHNO-FRONTIER is one of the largest exhibitions in Asia, where the latest technologies and products in mechatronics, electronics and related specialized fields are exhibited. We exhibited "Electromagnetic Wave Reflective Ink/Absorption Ink" and "Non-Conductive Ink" at the 36th EMC Japan Expo. We also introduced our "High Definition Ink," decorative inks that can be used in combination with other inks.

- Period

- Jul 26 - Jul 28, 2023

- Venue

- Tokyo Big Site

- Official HP

- https://www.jma.or.jp/tf/

List of Exhibits

1.Electromagnetic wave reflective/absorption ink

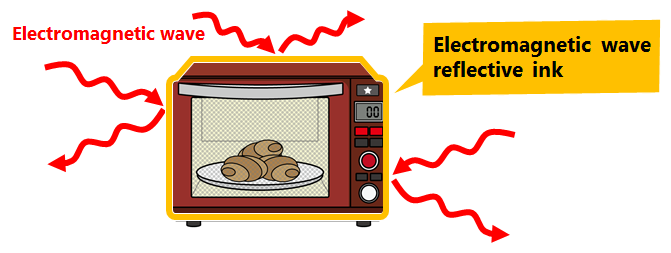

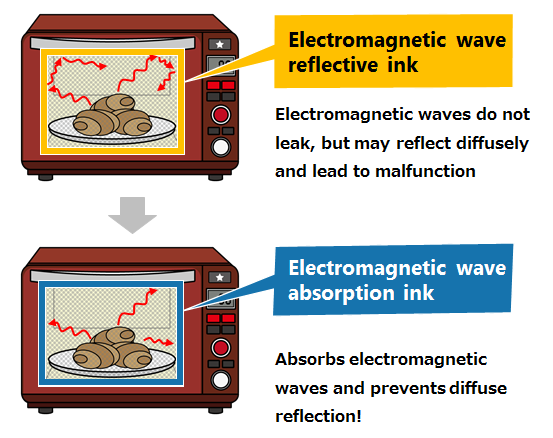

1.Difference between reflection and absorption of electromagnetic waves

- Electromagnetic wave reflective ink is required to block external electromagnetic noise.

- Electromagnetic wave absorption ink is required to block electromagnetic noise generated from inside the equipment.

Please feel free to contact us if you are interested in learning more about our products, as we will be happy to introduce suitable products based on your concerns.

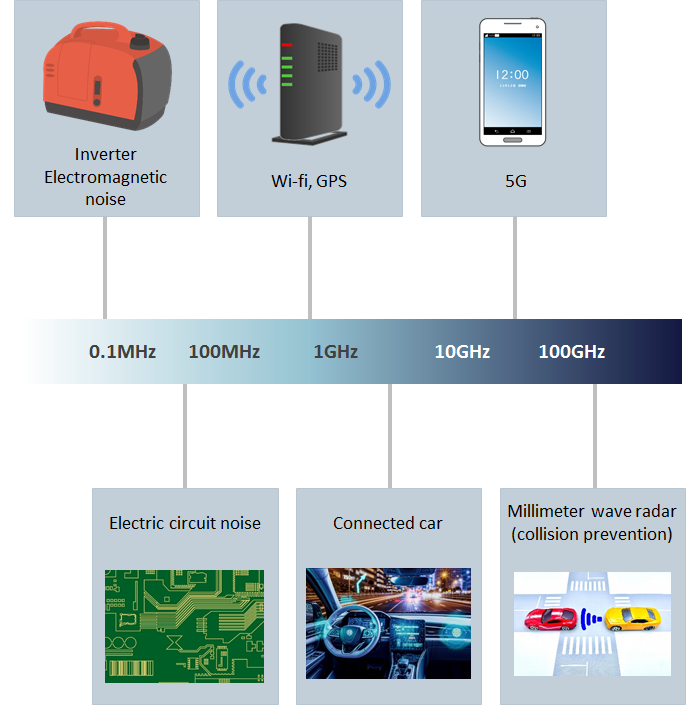

2. Equipment that requires electromagnetic wave countermeasures

Each product generates electromagnetic noise in different frequency bands, and these different electromagnetic noises can cause other products to malfunction.

Therefore, it is necessary for each product to take measures to prevent leakage of electromagnetic waves or to protect itself.

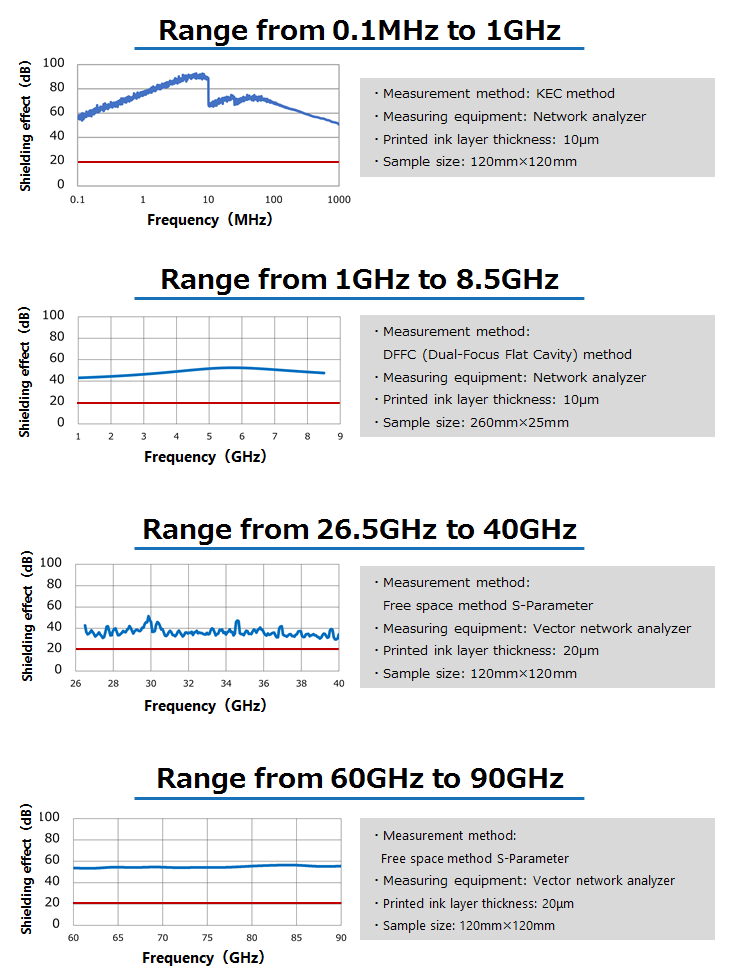

3.Reflection and absorption effects of electromagnetic wave reflective and absorption inks

Electromagnetic wave reflective and absorption inks can reflect and absorb electromagnetic waves in a wide range of frequencies with a single ink.

*However, absorption ink is still in the development stage.

1.Measurement

We prepared 3 types of acrylic cases and confirmed the effectiveness of the of the reflective/absorption ink in suppressing electromagnetic noise generated by the elevator button demonstrator.

Sample of acrylic cases

- Unpainted

- Painted(Reflective ink)

- Painted (Absorption ink) *Under development

1.Unpainted

Electromagnetic wave meter readings showed little change.

2.Painted(Reflective ink)

The value decreased from 102V/m to 0V/m.

3.Painted (Absorption ink) *Under development

The value decreased from 95V/m to 26V/m.

2.Performance

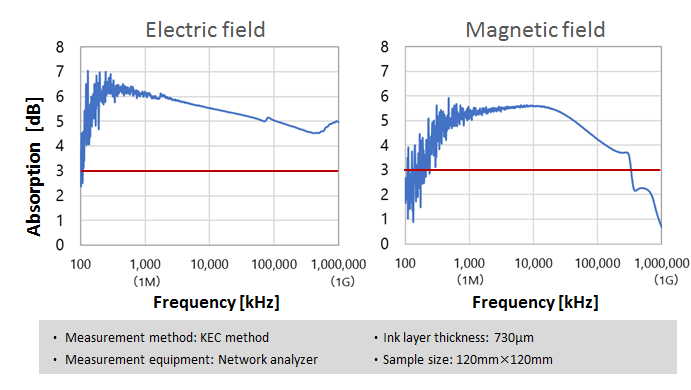

Below are the results of measuring the reflection and absorption effects versus frequency.

- Reflection

99% reflectance at 20 dB (red line).

- Absorption *Under development

50% absorption at 3dB (red line)

4.Type of electromagnetic wave shielding inks

Electromagnetic wave shielding ink are available in MRX-HF (for plastic) and GLS-HF (for glass).

We can also consider other ink types, so please contact us if you are interested.

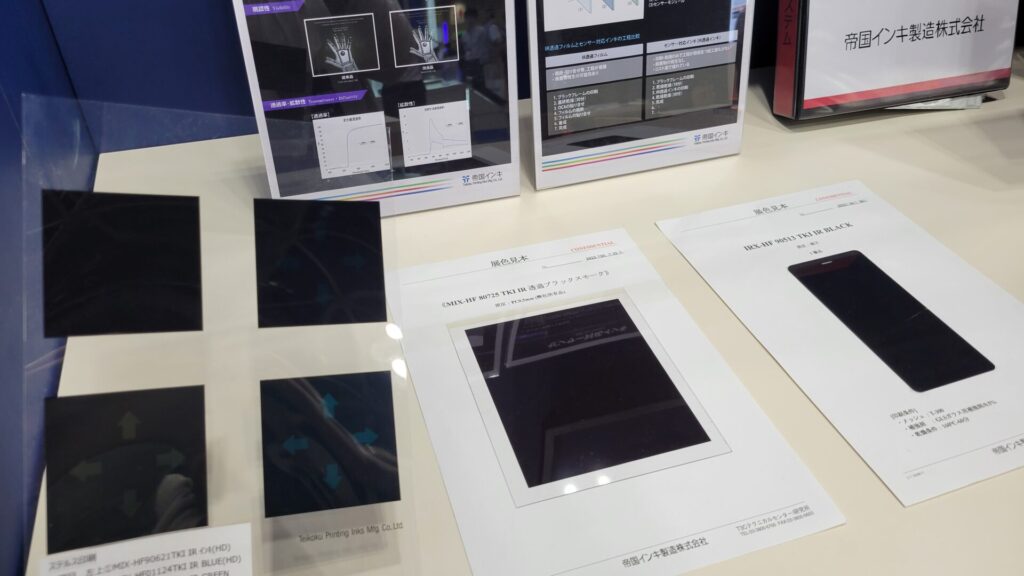

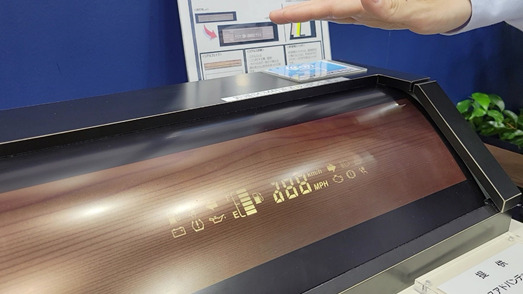

2.Ink for sensor (IR transmittable ink)

Ink for sensor appear to be black and impervious to light, but they do not allow visible light to pass through and allow infrared rays to penetrate. It is commonly used in remote control receivers for TVs and air conditioners, but recently it is also used to hide the lens of infrared camera lenses and the sensors of TOF (Time of Flight) sensor.

1.Examples

- An IR sensor is embedded in the machine where the hand is held, and ink for sensor is printed to hide it.

- When you hold your hand over it, the sensor reacts and the backlight turns on.

- The wood-grain printed material has dead front printing, and backlighting allows text and icons to be displayed.

For more information, please see below.

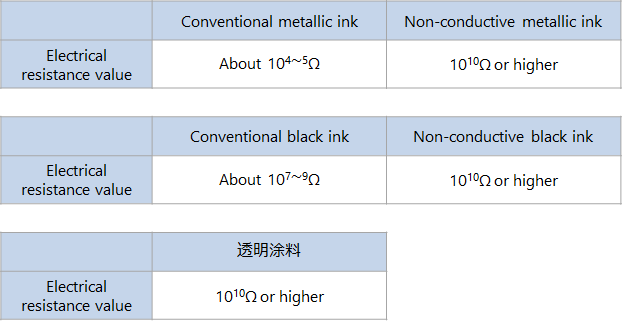

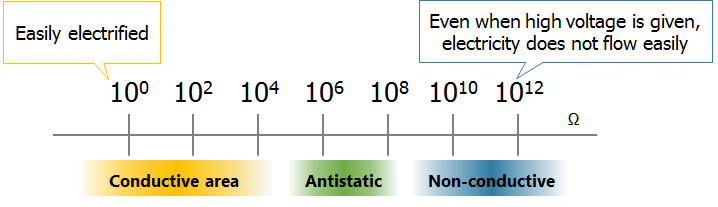

3. Non-Conductive Ink

1.Characteristics

- Resolves touch panel malfunctions, shorts in electrical circuits, and radio wave (antenna) interference caused by energized printed ink layer.

- Electrical resistance of non-conductive black and metallic inks is 1010Ω or higher.

- Enables metallic design on electronic devices, which was previously considered difficult to achieve.

- It is possible to create inks for each base material (glass, PET, PMMA, etc.)

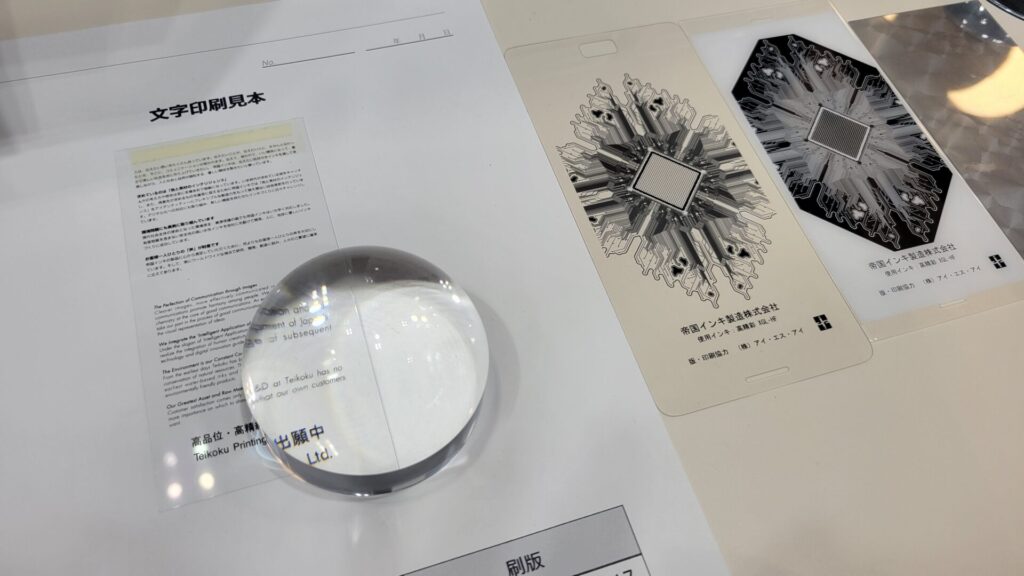

4.高精彩インキ High Definition Ink

As the name implies, High Definition Ink excel at printing high definition designs, but they also have other features that are pleasing to designers and operators.

1.Advantages and disadvantages

Advantages

Design

- Fine printing (More delicate designs can be achieved by combining with stainless steel plates)

- Uneven solid printing (Also possible with metallic ink)

- Hard to bleed.

Workability

- Fast and continuous printing

- Reprinting is possible (ink can be left on the plate for 60 minutes and still print without clogging)

- Reduce the number of stencil washes

Disadvantages

Since this is a slow-drying ink, a printed ink layer cannot be formed in a short drying time.

Please refer to the recommended conditions in the catalog and dry thoroughly in a dryer.

2.High Definition Ink series

5.You can view the exhibition!

- Related technical information

-

- Ink for sensor realizes even higher performance

- Ink for sensor

- Introduction of IR transmittable ink (IR Transmitting Ink) and concealed printing

- Conductive ink that allows free setting of resistance value

- Electromagnetic wave shielding ink

- Introduction of High Quality and High Definition Screen Printing Ink

- Introduction of Non-Conductive Black ink

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.