Past events

Exhibition Report of JFlex 2023

Event outline

JFlex 2023 will bring together materials and technologies that enable new electronics, including wearable device that read people’s vital sensing, automotive seat sensor, as well as foldable display, battery, and sensors that can be attached to curved surface. We exhibited “Dead front printing” that can hide display, camera, etc., and its application “Changing technology”, examples of “Electromagnetic wave shielding” realized by screen printing that has been conventionally controlled by metal or film, and "High transparency Black IR transmittable ink" that can blindfold sensors without damaging sensor functions.

- Period

- Feb 1 - Feb 3, 2023

- Venue

- Tokyo Big Site

- Official HP

- https://www.convertechexpo.com/

List of Exhibits

- 1.Decoration technology of non-contact switch

- 2.Inks for electromagnetic wave shielding that contribute to product weight reduction

- 3.Sensor ink for self-driving and safe driving.

- 4.Collaboration of sensor and stealth technology

- 5.Dead front printing application that changes the images with backlight.

1.Decoration technology of non-contact switch

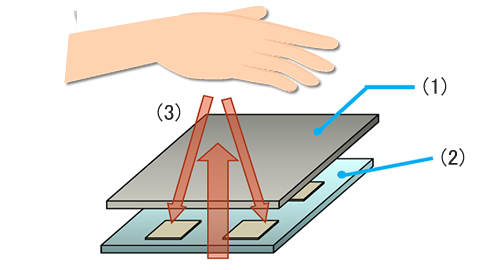

1.What is a non-contact switch?

A non-contact switch can be turned on and off without touching it by a built-in infrared sensor detecting a hand held. By printing sensor inks on the infrared light emitting/receiving port, it is possible to create a design that does not make the user aware of the built-in sensor.

(1) Cover glass on which sensor ink was printed

(2) Sensor body (IC chip)

(3) The sensor emits and receives Infrared rays.

2.Sensor ink that expands the possibility

Sensor inks are capable of adjusting the transmission wavelength and transmittance to suit the type of sensor built-in. Therefore, they can be used for variety of products with built-in sensor.

What sensor inks can do;

- Capable of creating free designed switches that take advantage of characteristic of screen printing.

- Can be designed to hide the sensor (Seamless)

- Combined with Dead front printing, information can be displayed when only needed.

3.Application to products with built-in sensors (non-contact button)

In recent years, contactless has become increasingly common in places that are touched by an unspecified number of people.

The following is a printed material that enables non-contact selection for buttons on elevator, etc.

An infrared sensor is built under the arrow, and when a finger is placed close to the button, the sensor reacts and the edge of the button glows blue.

Exhibition Cooperation: Elevisor Japan Inc., TOA Electronics, Inc.

2.Inks for electromagnetic wave shielding that contribute to product weight reduction

1.What is electromagnetic wave shielding ink?

Electromagnetic wave shielding ink is a type of conductive ink in which a conductive coating film blocks (shields) the penetration and leakage of electromagnetic waves. Compared to other shielding materials (metal plates), it is lightweight, thin, and has superior functionality such as high moisture resistance.

The following is an example of electromagnetic waves (radiated electric field) radiated from a PC shielded with the printed material made of electromagnetic shielding ink. The radiated electric field is shielded from the normal measured value of 204 V/m (left) to 24 V/m (right).

2.Characteristics of electromagnetic wave shielding ink

Electromagnetic shielding ink has four characteristics.

- Light weight and thinning can be achieved by combining with resin materials

- Adhere to a wide range of materials

- Pattern print, only necessary part, is possible.

- With only one type of ink can shield a wide range of frequencies (from 0.1MHz to 90GHz).

Unlike other electromagnetic shielding materials, this product has both electromagnetic shielding effect and merits of screen printing.

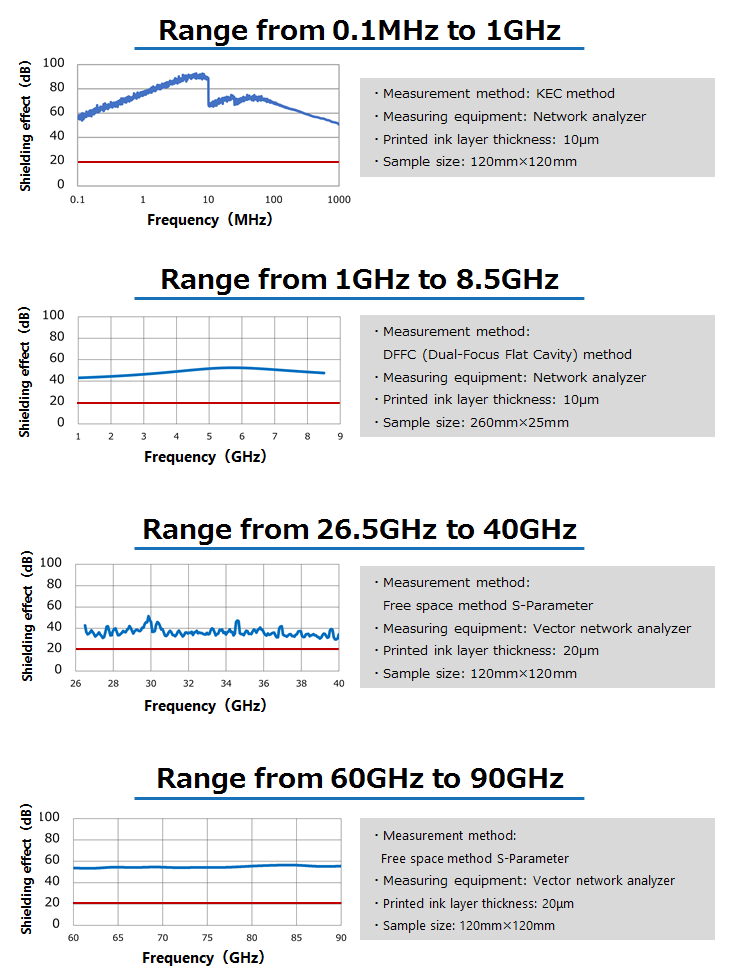

3.Performance of electromagnetic wave shielding ink

Shielding effect of electromagnetic wave shielding ink can be adjusted depending on the resistance value and the printing conditions of ink. The following are the results that shielding effect in each frequency range was measured.

4. How to use electromagnetic wave shielding ink

(1) Screen printing: Shield function can be printed in the shape of the required area.

(2) Spray Painting: Can add electromagnetic shielding function by spraying ink directly on the product.

5.Type of electromagnetic wave shielding inks

Electromagnetic wave shielding ink are available in MRX-HF (for plastic) and GLS-HF (for glass). Both inks can be used for electromagnetic shielding and decoration. In case of decoration with color other than standard color, free expression is possible by overprint with regular inks.

3.Sensor ink for self-driving and safe driving.

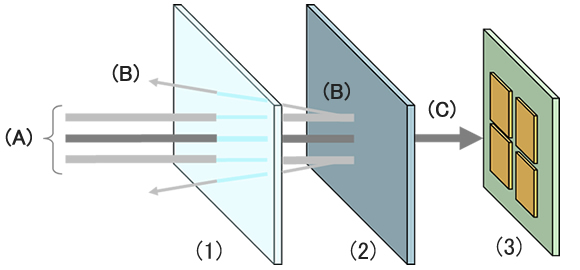

1.What is sensor ink (IR transmittable ink)?

Sensor ink, also called IR transmittable ink, is a decorative ink which blocks visible light and UV rays causing sensor malfunction and transmits only infrared rays. By replacing the IR transmissive film that is used for an IR transmissive part with sensor ink, decorating IR transmissive part is possible. Moreover, sensor ink contributes to cost reduction because printing processes are fewer than film attaching processes.

(A)IR and visible light and UV rays causing malfunctions,

(B)Visible light and UV rays blocked (absorbed or reflected) by ink for sensor,

(C)Transmitted IR

(1) Product body (PC, PET film, glass), (2) Sensor ink, (3) Sensor module

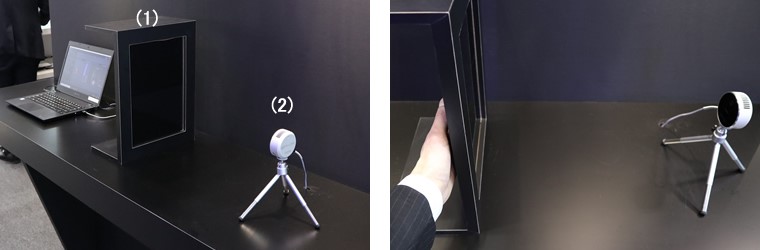

2.Transparency of sensor ink using infrared camera

Below, from right to left, are “LiDAR Sensor with infrared camera (2)”, “Printed material printed with sensor ink and regular black ink (1)”, and “PC” showing the image from infrared camera.

When a printed material (1) is placed in front of camera (2) and a hand is held up on the opposite side of infrared camera, the side (top) with the sensor ink printed on it shows the hand clearly.

As future market development, it can be considered for use in components that require high-precision image recognition, such as camera lens blindfolds for driver status monitors that check the driver’s movement, and LiDAR sensors.

4.Collaboration of sensor and stealth technology

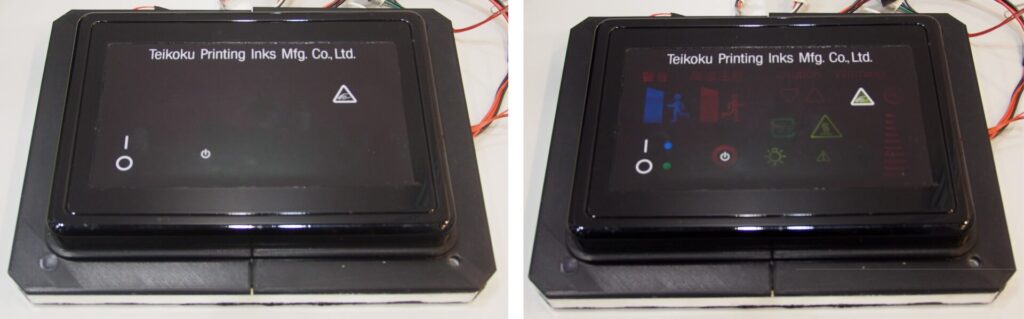

1.Non-contact switch and dead front printing

Non-contact switches using sensor ink and dead front printing can be used to create the product that displays the information when needed.

The following may look like a carbon pattern, but when you hold your hands over it, non-contact switch is activated and the hidden information is displayed.

Exhibition Cooperation: Nisshinbo Micro Devices Inc.

2.Smart Surface

Smart Surface means literally a smart surface which indicates a surface material with multiple functions and high performance. We consider this technology to be both “functional smartness” that display information when needed and “design smartness” that related to decoration.

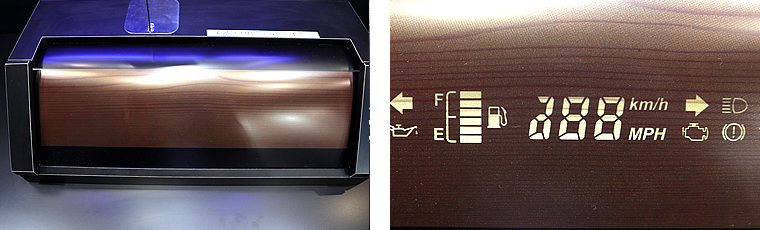

The following is the reproduction of high quality Dead front printing and wood pattern by taking advantage of the characteristics (fine printability and high opacity) of High Definition ink and high opacity black ink.

Real wood like design with High-Definition Inks (left photo) and information displayed with Dead front printing.

Provided by the company: KODENSHI TK CORP., NS Advantech Co., Ltd.

3.Module for Haptic feedback + Motion sensor + Dead front printing

A module for Haptic feedback is a device that generates feedback (vibration) when a switch on the screen is pressed. We would like to introduce a demo unit that uses this functionality, sensor, and Dead front printing to create an image of daily scene.

When the switch is not turned on, nothing appears on the screen due to Dead front printing. When you hold your hand over the lower left circle, the sensor reacts and the light inside turns on, displaying the hidden illustration. Then, when you press the illustration on the screen, vibrations are fed back to your finger.

5.Dead front printing application that changes the images with backlight.

1.A mechanism for displaying different designs in the same parts.

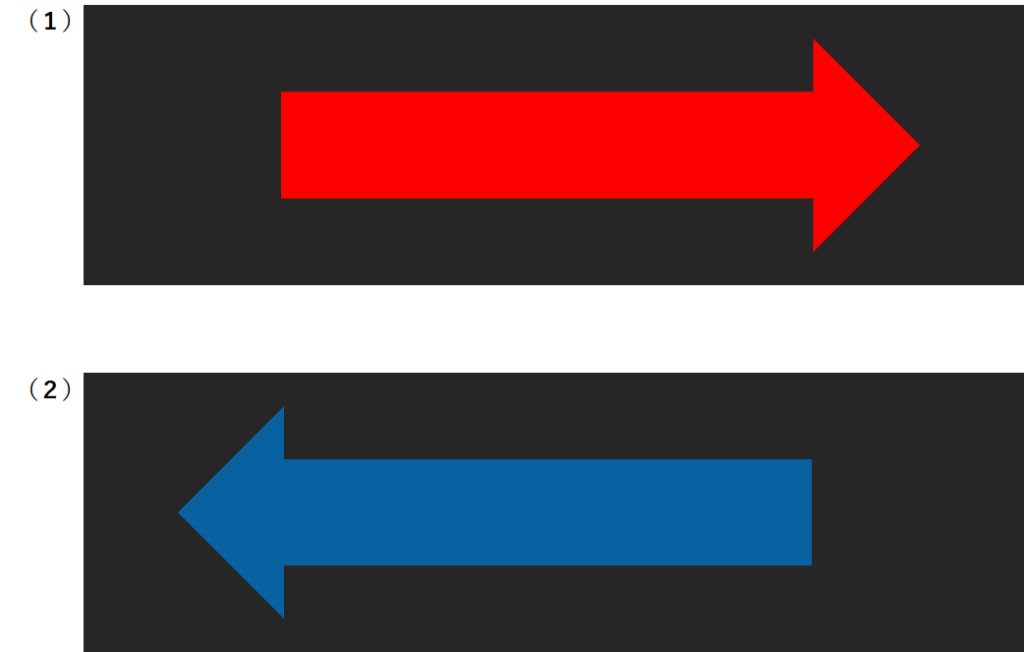

Dear front printing enables multiple switchable designs to be applied to same parts by devising the light source and the wave length of transmittance light.

For example, using light sources with wavelengths of red (wavelength: 580 to 780 nm) and blue (wavelength: 430 to 490 nm) as backlight, images are drawn by combining inks that selectively transmit each light source (inks that transmit only red light, inks that transmit only blue light, and transparent areas that transmit both), respectively. As a result, an image with a red light-transmitting section when red light is irradiated and an image with a green light-transmitting section when green light is irradiated can be expressed on the same area.

(1) Image when irradiated with red light

(2) Image when irradiated with blue light

Image of combination of only red light transmission, only blue light transmission, both are transmission, and both are non-transmission

(3) Pearl、(4) Substrate、(5) Smoke ink、(6) Light shielding black、(7) Light shielding black、

(8) Ink transmitting only red wavelength、(9) Ink transmitting only blue wavelength、

(10) Two light sources, red and blue

2.Switching images on the same part

By using the above mechanism, it is possible to apply two images on the same part using different red and blue light sources.

Below is an example of two different designs for right and left pointing arrows, one with red light irradiated and other with blue light irradiated.

Exhibit Cooperation: Wonder Future Corporation

- Related technical information

- Related event information

Please feel free to contact us about the inks, methods, and trial products we have introduced.