High Opacity and 3D decoration is also possible.

Not only High Quality & High Definition printing! High Definition Ink

We are pleased to announce to our customers who are considering decorative printing with high opacity and three-dimensional effect!

This ink series enables stable printing of fine designs that have been difficult with conventional inks.

In addition to fine designs, it is also capable of printing high opacity and thick printing with three-dimensional effect.

1.What is High Definition Ink?

1.1 Unprecedented screen printing ink that achieves both fine and solid printing.

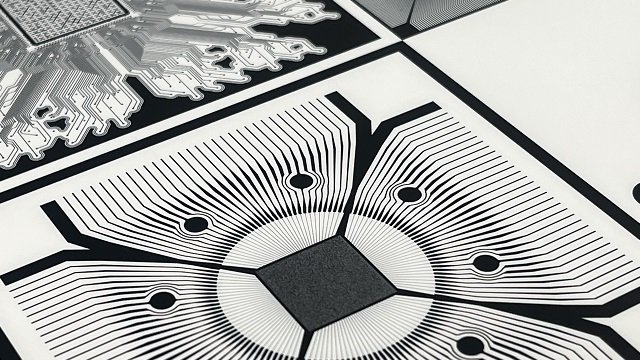

The High Definition Ink series is a unique ink that can achieve both fine and solid printing, which was difficult to achieve in the past. In addition, the High Definition Screen Ink System can print 100µm line with an accuracy of 100 to 116µm by combining ink, stencil, and printing technologies. It can faithfully reproduce designs that include fine lines and solids, and is expected to reduce defect rates and costs through the realization of fine designs and stable print quality, which have been difficult to achieve in the past.

|

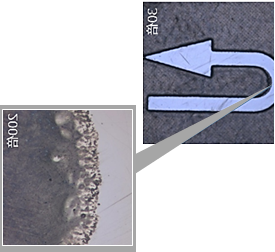

Conventional Ink |

High Definition Ink |

|---|---|

|

Outline spacing: 30µm Magnification X 200 |

Fine design can be realized simply by changing the ink! |

The lineup of the High Definition Ink series is as follows.

| Series | XER Series | XIP-HF Series | XGL-HF Series | XFM Series |

|---|---|---|---|---|

|

Type |

One component curing type |

Two component curing type |

Two component curing type |

One component curing type |

|

Material |

Treated PET・PC |

Treated PET・PC |

Glass |

PC |

|

Application |

Nameplate Membrane Switch panel |

Automotive Parts Home Appliances |

Display Touch panel Smartphone |

Automobile nameplate (Vacuum forming) |

1.2 Benefits of High Definition Ink

Here are 7 benefits of High Definition Ink series.

|

1)Fine Printability |

When printing a fine line of 100μm, conventional ink has a spread of ink sagging at 150μm, whereas High Definition ink can print a fine line of 100μm. In addition, 30μm printing can also be achieved under the recommended conditions. |

|

2)Solid Printing |

High Definition ink is suitable not only for fine printing but also for solid printing. Patterns that are difficult to achieve with conventional inks, such as solids and gradations, can be printed simultaneously. |

|

3)Saw Edge |

In frame printing for smartphones, tablets, and car navigation systems, saw edges (uneven straight lines) occur where the straightness of the frame cannot be obtained, but the High Definition ink can reduce the unevenness to 10μm or less. |

|

4)Continuous printability |

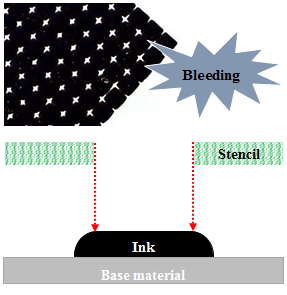

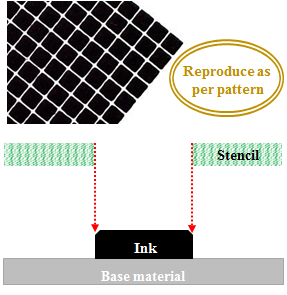

While conventional inks bleed after 300 consecutive sheets of printing, High Definition ink can print 1,000 consecutive sheets without any pattern change. |

|

5)High speed printing |

Fine printing is possible even at the high-speed printing of 1500 sheets per hour by a fully automatic printing press. |

|

6)Re-printability |

With conventional inks, when printing is temporarily interrupted due to positioning or other work, printing must be resumed after a washing process. However, with High Definition inks, even if printing is interrupted for an hour, printing can be resumed without a washing process after printing a few discarded sheets. |

|

7)Reduced cleaning frequency |

Conventional inks may require multiple stencil washes to maintain printing quality. However, high reproducibility and continuous printability of High Definition inks minimize the need for stencil washing during the printing process. |

2.High Opacity Black Ink

2.1 Seeking higher quality solid printing

High Opacity Black ink is an ink with excellent opacity for solid printing in addition to the high-quality and high-definition printability of High Definition ink.

By combining opacity and fine printability, it is possible to print outline characters on displays, etc. in a stable manner.

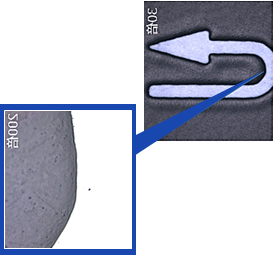

- Fine printability

|

Conventional Ink |

High Definition Ink |

|---|---|

- High Opacity

|

Conventional Ink |

High Definition Ink |

|---|---|

|

Mesh |

350 | 250 |

Mesh |

350 | 250 |

| Ink layer thickness | 3.2μm | 4.7μm | Ink layer thickness | 3.4μm | 4.6μm |

| OD Value | 3.8 | 4.2 | OD Value | 5.2 | 6.5 |

※The above are measurement results at our company and are not guaranteed values.

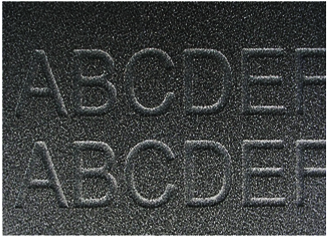

3.Thick printing ink with a three-dimensional effect

3.1 Three-dimensional printing not available with conventional solvent inks Seeking higher quality solid printing

The high viscosity and thixotropy unique to High Definition inks prevents bleeding and produces a thicker printed ink layer than conventional inks, enabling three-dimensional decorative printing that is not possible with conventional solvent inks.

|

Conventional Ink |

High Definition Ink |

|---|---|

|

|

- Related technology information

- Related event information

- Related inks