Adding High Value to Products with FIM/IMD

Adding High Value to Products with FIM/IMD (Part 1)

Adding High Value to Products with FIM/IMD (Part 1)

FIM/IMD allows new features that cannot be achieved with other production methods.

In this issue, our theme is improvement of product attractiveness through “Light Transmission Function”.

Definition of FIM/IMD:

FIM stands for “Film Insert Molding.” IMD stands for “In-Mold Decoration.” Both processes, FIM and IMD, involve “Inserting screen printed film into a mold and creating a product through the integral molding method.”

1. New Features Using a “Light” Transmission Function

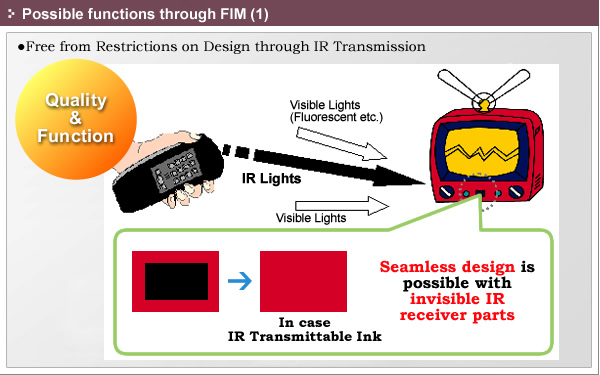

Achieve unique features in FIM applications through the use of ink that controls transmitted light by specifying the wavelength of IR or visible lights.

2.Infinite Design Variations Possible with the “Light” Transmission Function

We will introduce a wide range of design variation examples achieved through the use of the IR and visible light transmission function.

IR receiver parts will disappear from products through the use of the “IR Transmission” function!

Seamless designs for IR receiver parts on products are possible with use of IR transmission inks.

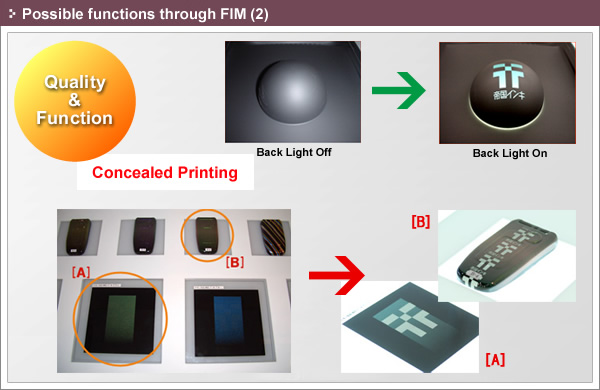

IR Receiving Parts can be concealed by combing with Metallic Ink.

Achieve Remarkable Features with Concealed Printing

Have a solid look on the outside with ability to transmit the light when the backlight is switched on.

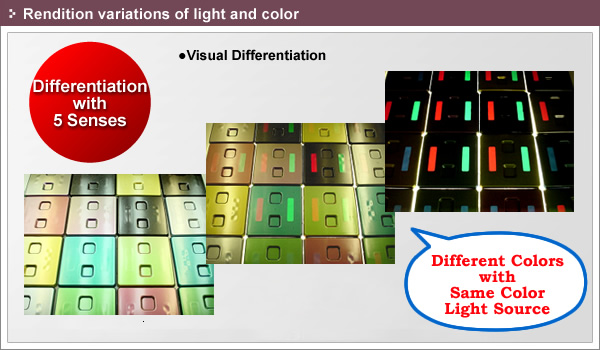

Combinations with Color Variation Presentations

Combinations of transmitted light and “color” are possible. Also the possibilities are infinite for “light” and “color” variations on backlit products.

- Related technology information

-

- 150: Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- 151: Technology lecture for FIM/IMD 2nd session: Explanation of the screen printing process.

- 152: Technology lecture for FIM/IMD 3rd session: Explanation of the Forming Process.

- 153: Technology lecture for FIM/IMD Final session: Explanation of the Injection Process

- Related event information