Techniques to Achieve a High Added Value of Products

FIM/IMD Technique(2)

Product Decoration Methods

Coloring resin and painting have been commonly used to color plastics. In recent years, a new decoration method has emerged that utilizing screen-printing and Film Insert Molding.

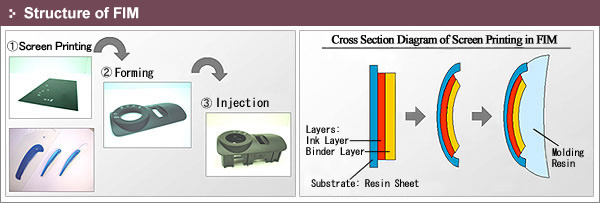

What is “Film Insert Molding?”

Film Insert Molding or In-Mold Decoration (FIM/IMD) is a “Method of inserting screen printed film into the mold and creating the final product through integral molding”

Enhanced Design with a New Decoration Method

(non-painting):

Functions of FIM Achieve Distinctive Added Value

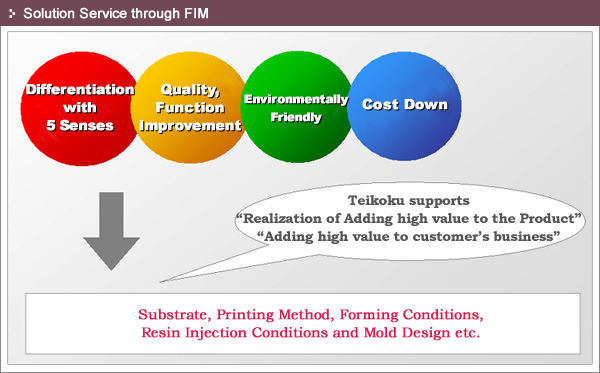

Teikoku’s support service enables you to create distinctive plastic products through high added value.

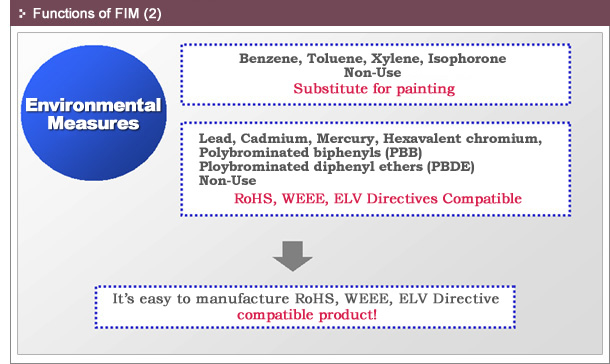

Reducing Environmental Risk

Recently, there is shocking news about accessories made with inexpensive plastics containing excessive amounts of lead. Teikoku’s service, adding high value to screen-printing and film insert molding related products, enables you to create products that are free of heavy metals in compliance with various countries’ restrictions.

Teikoku’s support service for adding high value to products

FIM Support Service

FIM technical support service is provided for any process.

<

- Related technology information

-

- 153: Technology lecture for FIM/IMD Final session: Explanation of the Injection Process

- 152: Technology lecture for FIM/IMD 3rd session: Explanation of the Forming Process.

- 151: Technology lecture for FIM/IMD 2nd session: Explanation of the screen printing process.

- 150: Technology lecture for FIM/IMD 1st session: Explanation of the merit and 3 process.

- Related event information