Product overview

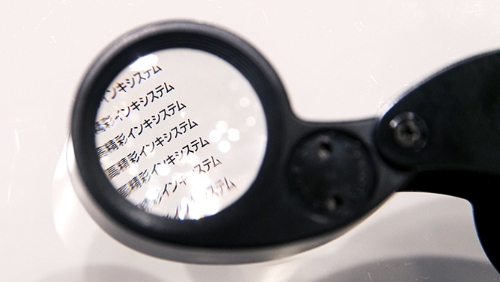

High Quality and High Definition screen printing inkscan produce solid printing and fine pattern faithfully and enables stable printing of 100µm width fine line with high accuracy. XER Ink is one pack type screen ink which is suitable for printing fine line or characters on name plate, etc., and provides printed ink layer with excellent flexibility and heat resistance at post-processing.

- High Definition Ink

Application

- Home appliance nameplates, automobile nameplates

-

Automobile, Motorcycle

-

Home Appliance (IoT)

-

Smartphone, Tablet, Smart watch

-

Sensor

-

Game

-

Others

Features, Function

- Enables extremely high precision printing such as 100μm width fine line and dot, etc.

- Excellent printing stability and high-speed printing printability.

- Printing ink layer provides excellent adhesion property.

- Standard colors with excellent weather resistance and heat resistance are available

- Multi color setting

- Fine printing

- High speed printing

- Fast dry, slow dry

Substrate

- Easy adhesion treated PET film, PC (Polycarbonate) film, sheet

- *Annealing(preheating) may be required depending on the material, so please check before use.

- PC

- Easy adhesion treated PET

Dilution

- XZ-705 SOLVENT Dilution: 0 to 5%

- *Defoamer and other agents may separate over time, please stir the ink thoroughly before use.

- *Do not use other solvents as they may adversely affect curing, adhesion, stencil stability, or other properties.

Promoter

- XSM-40 DEFOAMER Less than 1% (For anti-foam and improvement in leveling)

Recommended cleaner

- Screen Cleaner L2

Mesh

- L-355 Mesh (Coverage of 971 Black is about 80m2/kg at L-355 mesh)

- *Recommendation: L-screen 355 mesh made by NBC Meshtech

- *T 350 mesh can also be used for printing

Drying

- 80℃ 30 min

- Overprint

Each layer 80℃ 10 min(tack-free)

Final layer 80℃ 30 min

- *Insufficient drying may cause blocking, please dry thoroughly.

Standard colors

-

001 VICTORIA

-

168 SCARLET

-

177 RED

-

246 LIGHT YELLOW

-

277 REDDISH YELLOW

-

391 BLUE

-

526 ORANGE

-

581 MAGENTA

-

675 WHITE

-

797 GREEN

-

821 VIOLET

-

971 BLACK

- *Color settings for color separation (TC) are also available.

Caution

- Checking before production: Adhesion and resistance properties may change due to differences in substrates, processes, printing and drying conditions. Be sure to check the adhesiveness and resistance properties before mass production printing.

- Ink shelf life: 24 months from production date, unopened.

Safety

- UN No.: Not classified in the definition

- UN Classification: Not classified in the definition

Handling

- Use safety gloves and eyeglasses to protect skin and eyes. If the ink comes in contact with skin, wash with soap and plenty of water (or lukewarm water) and consult with a doctor.

- Containers should be closed tightly after use and stored in a cool and dark place.

- SDS is available upon request. Please request a copy and read it carefully before handling the products.

Resistance

| Test item | Test Conditions | Test results |

|---|---|---|

| Adhesion | JIS K 5600-5-6:ISO2409(cross-cut)、1mm interval 6×6、cellophane tape and peel off | 0(peel off) |

| Heat | 110℃、48 hrs.、check appearance and peel off from the substrate | No defect |

| Water | Soak 168 hrs. in tap water, check appearance and peel off from the substrate | No defect |

| Hot Water | Soak 48 hrs. in 40℃ warm water, check appearance and peel off from the substrate | No defect |

| Acid | Soak 24 hrs. in 5% HCl, check appearance and peel off from the substrate | No defect |

| Alkaline | Soak 24 hrs. in 5% NaOH, check appearance and peel off from the substrate | No defect |

| Alcohol | Gakushin scrub tester, cotton soaked ethyl alcohol, weight 500g, 50 back and forth, check peel off | No defect |

| Scrub | Gakushin scrub tester, cotton, weight 500g, 500 back and forth, check color fade | No defect |

| Falling-weight test | JIS K5600-5-3 DuPont Impact tester, drop 500g weight from 50 cm, | No defect |

| Bend test | JIS K5600-5-1: ISO 1519: (Cylindrical Mandrel) 2mmφ, check cracks | No defect |

| Punching | Punching by press machine | No defect |

| Accelerated Weathering | JIS K-5600-7-7:ISO 11341: (Xenon Lamp)Weather meter, BP Temp. 63+/-3℃ Raining rate 18 min/120 min, check color fade and peel off | 1000 hrs. No defect |

Test Condition

- Test conditions 【XER-971 BLACK】 【80℃ 30 min】 【L 355】【Substrate:0.5 mm Polycarbonate】

- Above resistance test results are measured results in our laboratory and they are not guaranteed values.

- Information contained in this catalog may change without prior notice.

FAQ

-

What is screen printing?

-

Screen printing is a type of stencil printing which uses a technique of duplicating the image from a design made on mesh stencils.

When printing ink goes through the mesh, it transfers the image onto the substrate material. Other than air and water, any substrate materials are printable. Not only flat surfaces, but also curved, specially shaped, and molded products are suitable for screen printing.

-

When over-printed with a black ink, we often have pinholes. How can we eliminate the pinholes?

-

See the list below for causes of pinholes:

1. The first layer is too thin (less than 5 µ)

2. Too much dilution of the ink (more than 20%)

3. Too much squeegee pressure

4. Under layer is pale colored, such as a medium based color

5. Any combination of these causes -

What are the standard drying conditions?

-

In multi-color printing, primary drying would be done after each color is printed. After the final color is printed, the final drying should be done according to the conditions listed in the catalog. If the color printed ink is a “two-pot” ink the final drying should be done after the printing of the Binder.

-

Why there is “Primary” drying and “Final” drying?

-

Residual solvent at the time of injection may cause ink flow and insufficient adhesion. To prevent these malfunctions, residual solvent must be evaporated through a “Final” drying process.

-

When we extended the primary drying time, pinholes and cracks resulted. How can we eliminate them?

-

With one-pot inks, if the primary drying time is too long, the solvent of second ink penetrates the first color layer and makes pinholes.

With two-pot inks, if the primary drying time is too long, a curing process occurs. Thus when the second color is printed, the first color ink layer wrinkles and looks like cracks. The countermeasure in either case would be to shorten the primary drying time.

- Related technical information

- Related event information

- Related inks