Product overview

Luminova ink for screen printing using “Luminova Phosphorescent”, long lasting luminescence time pigments.

- Functional ink

Application

- Glow in the dark sign, emergency sign (emergency exit, emergency stairs, emergency kit, etc.), decorations, etc.

- Clock-face

Features, Function

- Compatible with various types of UV and Solvent type screen inks by color matching.

- Significantly longer afterglow time than phosphorescent ink and contains no radioactive substances

Dilution

- 5 to 10% (Please refer to the solvent listed in the catalog for each ink type)

- *Stir well before every use, as phosphorescent pigments have a tendency to settle.

Mesh

- Lower than 150 mesh(Coverage is about 2 to 3 m2/kg with triple print at 100 mesh)

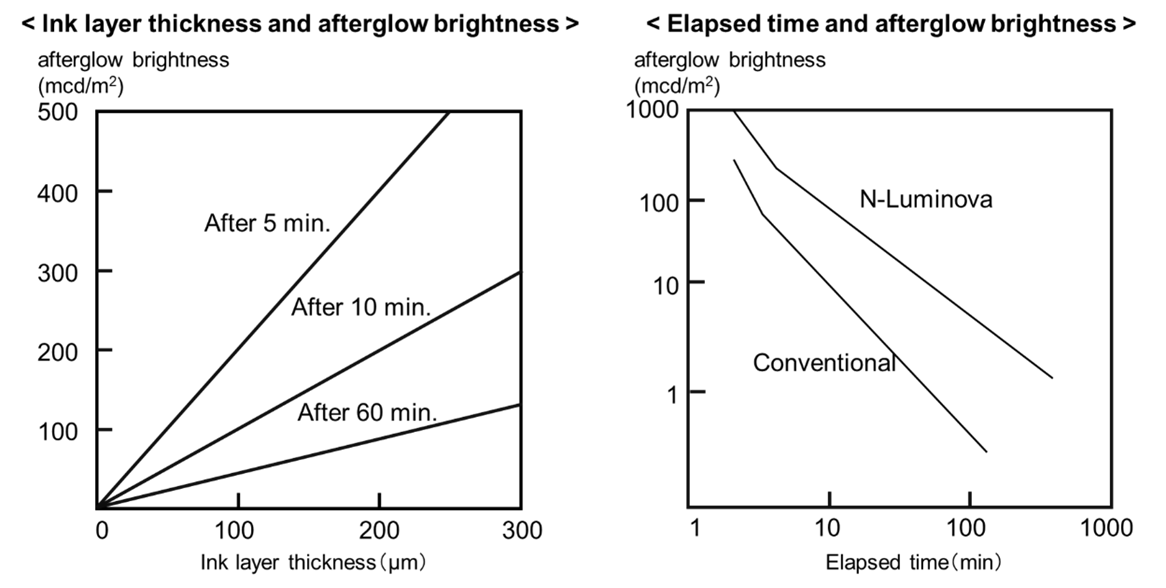

- *Maximum afterglow brightness is achieved at ink layer thickness of 400μm.

- *Select the mesh and emulsion thickness so that the ink layer thickness is at least 100-150 µm.

- *Triple print using 100 mesh stencil can produce ink layer thickness of about 150 to 200µm.

Drying, Curing

- According to each ink type.

Caution

- This product has tendency to precipitate due to high specific gravity of the pigments.

- Stirring ink every week or two will prevent precipitation.

- Ink shelf life: 3 months from production date, unopened.

Safety

- Please refer to respective ink catalog for transportation information.

Handling

- For flammability and flash point, please refer to the product catalog for each ink used.

- Use safety gloves and eyeglasses to protect skin and eyes. If the ink comes in contact with skin, wash with soap and plenty of water (or lukewarm water) and consult with a doctor.

- Containers should be closed tightly after use and stored in a cool and dark place.

- SDS is available upon request. Please request a copy and read it carefully before handling the products.

Resistance

| Test item | Test Conditions | VK-N Luminova | UV FIL-N Luminova |

|---|---|---|---|

| Adhesion | JIS K 5600-5-6:ISO2409(cross-cut)1mm interval 6×6, cellophane tape peel | 0 (no peel) | 0 (no peel) |

| Heat | 80℃ 72 hrs. check appearance and peel off | No defect | No defect |

| Alcohol | Gakushin scrub tester, cotton soaked ethyl alcohol, weight 500g, check peel off | (250 back and forth) No defect | (500 or more back and forth) No defect |

| Water | JIS K 5600-6-2 ,ISO 2812-2, Soak 24 hrs. in 40℃ tap water, check appearance and peel off | No defect No defect*1 | Abnormality No defect*2 |

| Oil | Soak 30 min in motor oil | No defect | No defect |

| Detergent | Soak 1 hr. in neutral detergent, check appearance | No defect | No defect |

| Abrasion | JIS K5600-5-9 ISO7784-2(Abrasion ring method), weight 500g, CS17 ring, number of times when substrate is exposed in abrasion ring | 120 times | 500 times or more |

| Bending | JIS K 5600-5-1 ISO 1519 (Cylindrical Mandrel), 2mmΦ, check cracks | No defect | No defect |

| Punching | Punching by press machine, JIS K 5600-7-5 ISO 2809 Irradiance 100W/m2 BP Temp. 63±3℃, check color fade and peel off | No defect | No defect |

| Light fastness | JIS K 5600-7-5 ISO 2809 Irradiance 100W/m2 BP Temp.63±3℃, check color fade and peel off | (500 hrs.) No defect (500 hrs.) No defect*1 | (500 hrs.) No defect (500 hrs.) No defect*2 |

| Accelerated Weathering | JIS K 5600-7-7 ISO 11341 Irradiance 60W/m2, BP Temp.63±3℃ Raining rate: 18 min/120 min、1000 hrs.,Check color fade and peel off | (200 hrs.) Abnormality (500 hrs.) No defect*1 | (200 hrs.) Abnormality (500 hrs.) No defect*2 |

- Remarks*1:SP-3100AU CLEAR (OVERCOAT) is printed once.

- Remarks*2:UV FIL-393 CLEAR (OVERCOAT) is printed once.

- Test Conditions

【SVC sticker】 【VK type: 60℃ 20 min】 【UV FIL type:80W/cm, two metal halide lamps, 10m/min】 【Various resistance tests are conducted on printed materials left for 48 hrs. after printing】

The following graph shows the relationship between the ink layer thickness and afterglow brightness. (VK Luminova ink was excited by 400 lux for 20 minutes)

- *Above resistance test results are measured results in our laboratory and they are not guaranteed values.

- *Information contained in this catalog may change without prior notice.

FAQ

-

What is Phosphorescent ink?

-

Phosphorescent ink contains pigments with luminescent properties that absorb and accumulate light rays from the sun, electric lights, etc., and gradually emit them, so the absorption-accumulation-emission process can be repeated many times. It can also be applied to safety and energy saving measures.

Related Links

Introduction of Luminova Phosphorescent Ink

Product Information: Phosphorescence Ink

Luminova Phosphorescent ink

- Related technical information

- Related event information

- Related inks